The Environmental Benefits of Using Stainless Steel Wire Mesh

As a versatile material, stainless steel wire mesh is widely used in various fields and is becoming more and more popular with environmental advocates and construction professionals. This article will deeply discuss the advantages of stainless steel wire mesh panels in terms of environmental protection, and explain their positive impact on the environment, aiming to promote the concept of green materials and promote sustainable development.

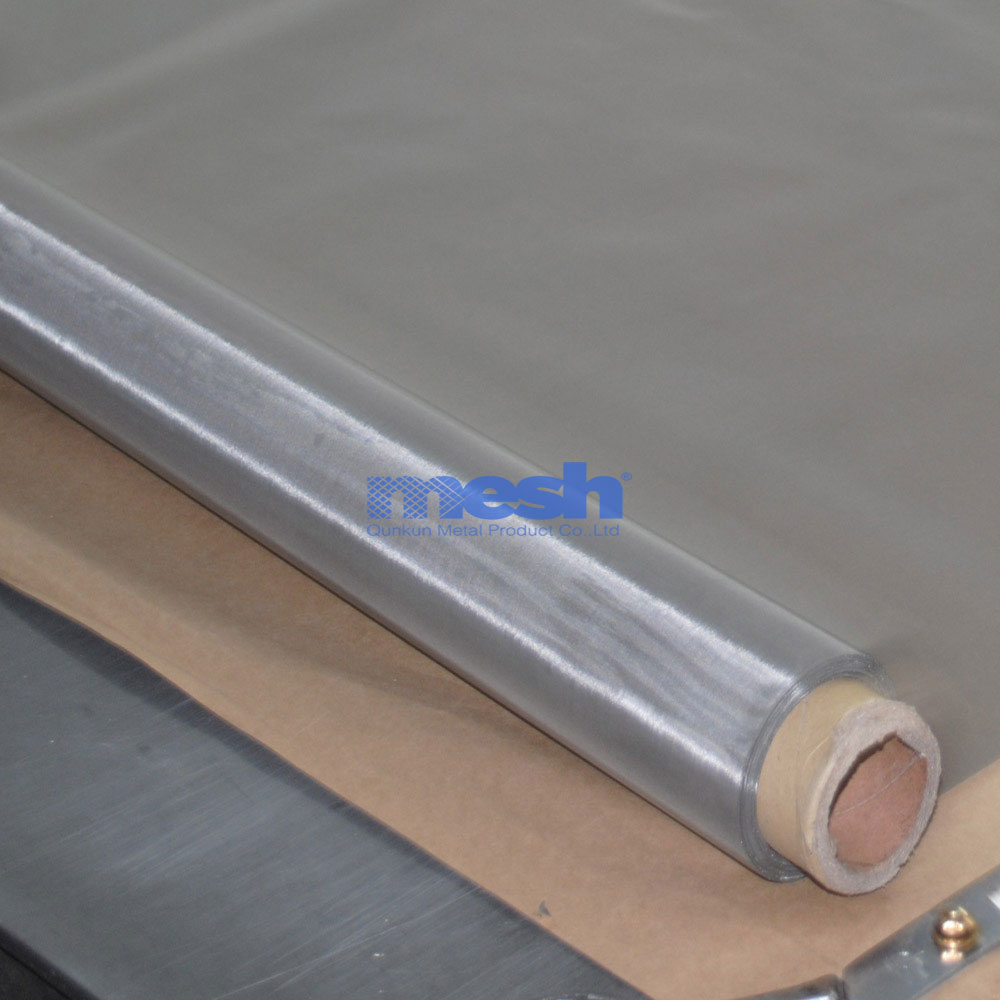

Durability and Sustainability

Stainless steel wire mesh panels are made of corrosion-resistant stainless steel for excellent durability and oxidation resistance. Compared with traditional iron or galvanized wire mesh panels, stainless steel wire mesh panels are more durable, have a long service life, and are less prone to corrosion and damage. Therefore, stainless steel wire mesh panels do not need to be replaced frequently, which reduces the consumption of natural resources and the generation of waste, which is in line with the concept of sustainable development.

Recyclability and Resource Conservation

Stainless steel wire mesh panels are recyclable materials. At the end of its useful life, stainless steel wire mesh panels can be recycled and reprocessed to be used again to produce new wire mesh panels or other stainless steel products. This recycling process helps to save limited natural resources, reduce the environmental damage caused by raw material mining, and reduce the demand for new materials, thereby reducing the overall environmental impact.

Low Carbon Emissions and Energy Conservation

Manufacturing stainless steel wire mesh panels generally produces lower carbon emissions than other metal materials. Stainless steel is produced using more environmentally friendly technologies, resulting in a smaller carbon footprint. At the same time, due to the high durability of stainless steel wire mesh panels, they are not easily damaged or deformed, which reduces the energy consumption required for maintenance and replacement, and saves energy for the environment.

-

Best Chain Link Fence for Security Applications Feb 10, 2026

Best Chain Link Fence for Security Applications Feb 10, 2026 Best Welded Wire Mesh for South American Markets Feb 03, 2026

Best Welded Wire Mesh for South American Markets Feb 03, 2026 Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026

Why Galvanized Wire Mesh Is Popular in South America Jan 26, 2026 How to Check the Quality of Welded Wire Mesh Jan 16, 2026

How to Check the Quality of Welded Wire Mesh Jan 16, 2026

- Tel.: +86 311 83077076

- E-mail: sales@qunkunmetal.com

- Skype: qunkunsales01

- WhatsApp: 8618032412189

- Add.: No.69 The Filter Industrial Part of Anping, Hebei, China